FIBER REINFORCED POLYMERS

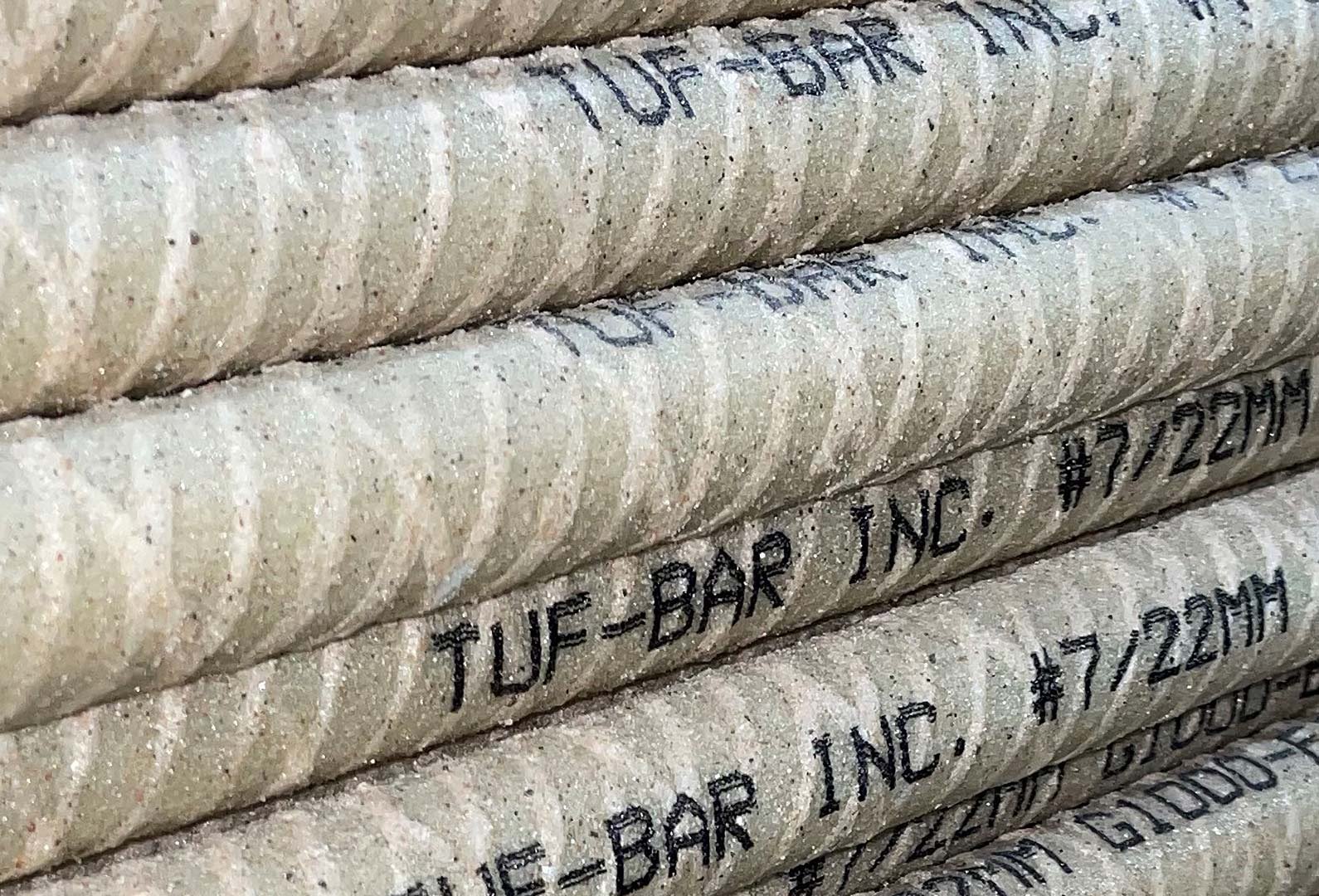

Fiber Reinforced Polymer, or FRP, is a generic term to describe a composite material made by combining fibers in a matrix reinforced with a polymer, resulting in strong, lightweight material formed into reinforcing bars, grids, mats, or other forms. The most common fibers used to create FRPs are glass, carbon and basalt.

FRP materials, when used for reinforcing or repairing concrete, have twice the tensile strength of steel reinforcement, weigh 25% of steel and are non-corrosive and non-conductive

The FRP Institute, formed in 2022, is a trade group whose primary purpose is to promote the increased use of fiber-based polymer reinforcement in concrete infrastructure such as bridges, roadways, seawalls and related structures. The FRP Institute collaborates with federal agencies, state DOTs, AASHTO, standards-setting groups and academia to increase awareness of FRPs, certify manufacturers, standardize specifications, test FRP materials and develop technical educational programming.

About the FRP Institute

FRP Institute Activities

The FRP Institute is an independent third-party FRP manufacturing plant auditor. The audit and certification program provide the following tasks:

FRP manufacturing plant audit

Management of independent plant certification program

Performance of independent inspections on behalf of DOTs and other owners

Audit and inspection training courses for engineers and QC personnel

Internal audit training

Development and maintenance of a Quality Control Manual based on ACI, AASHTO, FIB, CSA and other standards

FRP Audits

The FRP Institute collaborates with NTPEP, the National Transportation Product Evaluation Program, to certify FRP manufacturers for inclusion on DOT qualified vendor lists. Manufacturers must pass the FRP Institute audit to be eligible for certification under the NTPEP evaluation program. The goal is to advance the acceptance of composites to:

Provide a high degree of quality assurance for DOTs and other owners

Eliminate the need for DOT personnel to monitor manufacturing plants

Create a level of confidence among infrastructure owners who are selecting FRP reinforcement from certified producers for their projects

To ensure the high-quality audit services, we hold the Lead Assessor Certification for ISO/IEC 17020 by the ANSI National Accreditation Board. ISO/IEC 17020 is an essential standard for any organization seeking to perform inspections.

FRP Institute Leadership

Richard Krolewski

Founder and CEO

Richard Krolewski has 20 years of experience working to develop certification programs for precast concrete manufacturers and serving as a liaison between the precast industry and federal, state and local transportation officials. In addition to developing longstanding relationships with dozens of Departments of Transportation, he has worked with the Federal Highway Administration, the U.S. Department of Defense, the U.S. Army Corps of engineers and many local governments, specifying agencies and engineering firms.

W. Cabell Garbee II, P.E.

Chairman of the DOT Advisory BOD

Manufactured Products Engineer | Materials and Tests Unit | North Carolina Department of Transportation

Cabell Garbee manages the NCDOT’s acceptance programs for metals, concrete, timber, plastics and composite products used by the Department. Responsibilities include facility audits and approvals, product evaluations and inspections. He is responsible for materials product tracking by use of RFID/barcode identification and participates in the Department’s specification development. He is the Co-Chair of the AASHTO Product Evaluation Program Composite Concrete Reinforcement Committee, chairman of the DOT Advisory BOD, and a Professional Engineer licensed in North Carolina and Virginia.

Joseph Stilwell, P.E.

Auditing Chair/Technical Services Chair

Subject Matter Expert, U.S. Army Corps of Engineers Inland Navigation Design Center

As a subject matter expert for the Army Corps’ Inland Navigation Design Center, Joe provides engineering, design, analysis and review services for studies, new locks, new navigation dams, major rehabilitation of existing inland navigation locks and dams, and significant inland navigation lock and dam operations and maintenance projects.

In his previous position as a fabrication engineer with the Maine DOT, Joe worked in bridge construction, structural design and project management. As structural designer, he actively worked with composites and developed (in conjunction with Kenway Composite) an FRP Pile wrap system for making in-service repairs to pipe piles that doesn't require annular grout. Joe is a steering committee member of AASHTOs’ National Transportation Product Evaluation Program, a member of COMP TS-3b (Fresh Concrete) and TS-4f (Metals), and provides composites fabrication guidance to the vice-chair of T-6 (FRP Composites). He is an ACMA-certified composites technician-VIP.

Dr Rudolf (Rudi) Seracino, M.ASCE, F.ACI, F.IIFC

Lead Auditor

Professor of Structural Engineering | Department of Civil, Construction, and Environmental Engineering North Carolina State University

Dr Rudi Seracino has more than 20 years of research experience in the application of FRP materials and systems in civil infrastructure. He has a record of successful technology transfer of FRP reinforcement and systems for concrete bridges with the NCDOT. He is a voting member of: ACI Committee 440 on FRP Reinforcement; ASTM International Sub-Committee D30.10 on Composites for Civil Structures; PCI FRP Committee; and the NSF International Product Category Rule (PCR) Committee on Composite Products. Dr. Seracino is also a member of the ACMA FRP Rebar Manufacturers Council and is an Editorial Board Member of the ASCE Journal of Composites for Construction. He is a Fellow of ACI and the International Institute for FRP in Construction.

Matt Chynoweth, P.E.

Codes and Standards Chair

Vice President/National Bridge Discipline Leader RS&H

The former Chief Bridge Engineer for MDOT, Matt joined the architectural and engineering firm RS&H in 2023, bringing more than 22 years of experience in structural analysis, design, constructability review, and independent technical review of complex bridges. These include cable-supported bridges, post-tensioned concrete bridges, damaged bridge assessments, and load ratings. As MDOT Chief Bridge Engineer, he developed MDOT technical policy for large, complex, and movable bridges and implemented bridge-related policy and procedure to ensure compliance with AASHTO, FHWA, and all applicable technical, quality, and safety standards related to national bridges. Matt is currently serving as Owner’s Engineer on the RS&H Gordie Howe International Bridge Owners Representative contract with MDOT. Matt chairs TRB AKB10: Innovative Highway Structures and Appurtenances and is a member of ACI 440. He also teaches Bridge Design and Engineering at the University of Michigan and Lawrence Technological University.

- W.Cabell Garbee II, P.E. (Chairman of the DOT Advisory BOD)

NCDOT Manufactured Products Engineer Materials and Tests - Rachel Cano, P.E.

TXDOT Pavements and Concrete Materials, Tests Division - Richard Giessel, P.E.

Alaska DOT & Public Facilities State Quality Assurance Engineer - Jimmy Gutierrez. P.E., Ph.D.

CALTRANS Senior Bridge Engineer, FRP Specialist, Office of Earthquake Engineering, Analyst & Research Division of Engineering Services - Paul Hamzavi

Maine DOT, Assistant Fabrication Engineer - Chris Leibrock, P.E.

Kansas DOT Assistant Bureau Chief/Materials Lab - Sean Li, P.E., Ph.D.

VDOT Concrete Program Manager, Materials Division - M. Jason Mellons, P.E.

TNDOT Concrete & Aggregate Engineer - Dan Miller, P.E.

Ohio DOT State Materials Engineer - Joshua Moore, P.E.

Materials Engineering and Testing (METS) Branch Chief - Steve Nolan, P.E.

FDOT Advanced Materials for Structural Durability & Resiliency, State Structures Design Office - Tanarat Potisuk, P.E., S.E., Ph.D.

Oregon DOT Concrete Bridge Standards Engineer - John Schuler, P.E.

VDOT Assistant State Materials Engineer /Materials Division - Joseph Stilwell, P.E.

Maine DOT Fabrication Engineer, Bridge Programs - Walter Tayler, P.E.

GDOT Assistant State Project Review Engineer

- Tarek Alkhrdaji, P.E., Ph.D.

Structural Technologies - Scott Arnold, P.E.

FYFE - Gregg Blaszak

Coastal Composites - Michael Brown, P.E.

Simpson Strongtie - Matthew Chynoweth, P.E.

RS&H Engineering - Allen Fiford

GFRP Tech and GFRP Institute of South Africa - Borna Hajimiragha, P.E.

MST Bar - Tomas Jimenez, P.E.

Fyfe - Sho Nakahama

Tokyo Rope USA - Adam Sander, P.E.

Tuf/Bar - Rudolph Seracino, Ph.D.

NC State University Department of Civil Construction and Environmental Engineering - Xavier Seyanave, P.E.

Pultrall/VROD - Griff Shapack, P.E.

Simpson Strongtie - Joe Sorenson

Strongwell Companies - Toufic Traboulsi

SFTec Inc. - Eri Vokshi, P.E.

Sika - Danielle Kleinhans PHD.P.E.

Mateenbar Composite Reinforcements - Trevor Gundberg

Vectorply Corporation